Structural Steel Pipe

Classification :

Seamless Pipe

Key Words:

Seamless Pipe

Product introduction

Structural Steel Pipe

Pipe Type: Structural Pipe, Structural Seamless Pipe, Seamless Structural Pipe

Application: In Structural Engineering and Construction Industry

Specification: OD: 1/8'' ~ 26'' (10.3 ~ 660mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard: ASTM A53/A252/A500/A501, JIS G3444, EN 10210/10219

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Specification of Structural Steel Pipe

| API 5L/ASTM A106 GR.B, Structural Steel Pipe | ||||

| 公称通径 DN | 外径OD(mm) | SCH40(6m/5.8m) | SCH40(6m/5.8m) | SCH40(6m/5.8m) |

| 壁厚WT | 壁厚WT | 壁厚WT | ||

| (mm) | (mm) | (mm) | ||

| 1/4'' | 13.7 | 2.24 | 3.02 | / |

| 3/8'' | 17.1 | 2.31 | 3.2 | / |

| 1/2'' | 21.3 | 2.77 | 3.73 | 4.78 |

| 3/4'' | 26.7 | 2.87 | 3.91 | 5.56 |

| 1'' | 33.4 | 3.38 | 4.55 | 6.35 |

| 1-1/4'' | 42.2 | 3.56 | 4.85 | 6.35 |

| 1-1/2'' | 48.3 | 3.68 | 5.08 | 7.14 |

| 2'' | 60.3 | 3.91 | 5.54 | 8.74 |

| 2-1/2'' | 73 | 5.16 | 7.01 | 9.53 |

| 3'' | 88.9 | 5.49 | 7.62 | 11.13 |

| 3-1/2'' | 101.6 | 5.74 | 8.08 | / |

| 4'' | 114.3 | 6.02 | 8.56 | 13.49 |

| 5'' | 141.3 | 6.55 | 9.53 | 15.88 |

| 6'' | 168.3 | 7.11 | 10.97 | 18.26 |

| 8'' | 219.1 | 8.18 | 12.7 | 23.01 |

| 10'' | 273 | 9.27 | 15.09 | 28.58 |

| 12'' | 323.8 | 10.31 | 17.48 | 33.32 |

| 14'' | 355.6 | 9.53 | 11.13 | 19.05 |

| 16'' | 406.4 | 9.53 | 12.7 | 21.44 |

| 18'' | 457 | 9.53 | 14.27 | 23.83 |

| 20'' | 508 | 9.53 | 15.09 | 26.19 |

| 24'' | 610 | 9.53 | 17.48 | 30.96 |

Technical data

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition (%) | Mechanical Properties | ||||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | ||

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 | |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | ||

| ASTM A179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | - | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | - | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | - | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | ||

| GB/T8163 | 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.25 | ≤0.25 | 335-457 | ≥205 | ≥24 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | 410-550 | ≥245 | ≥20 | |

| Q345 | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.045 | ≤0.045 | - | - | - | 490-665 | ≥325 | ≥21 | |

Structural Steel Pipe Tolerance

| Pipe types | Pipe Szie(mm) | Tolerances | |

| Hot rolled | OD | All | ±1% (min ±0.50mm) |

| WT | All | +15%, -12.5% | |

| Cold drawn | OD | 6~10 | ±0.20mm |

| 10~30 | ±0.40mm | ||

| 30~50 | ±0.45mm | ||

| >50 | ±1% | ||

| WT | ≤1 | ±0.15mm | |

| >1~3 | +15% -10% | ||

| >3 | +12.5% -10% | ||

Structural Steel Pipe End

| Plain End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) | Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings | Outside Diameter equal or less than 2'' |

| Thread Protection | Outside Diameter over 4 inch |

Packing and delivery

With rich experience and excellent reputation in the steel industry, it is committed to providing the highest quality and applicable steel products to customers around the world and is a large rebar production base in China.

Factory

Dedicated to providing the best quality and applicable steel products for customers all over the world, and is a large-scale rebar production base in China.The main products are rebar, plate, hot rolled sheet, cold rolled sheet, galvanized sheet, color coated sheet, round steel, profiled steel, profiled steel, wire rod, steel rails and so on.

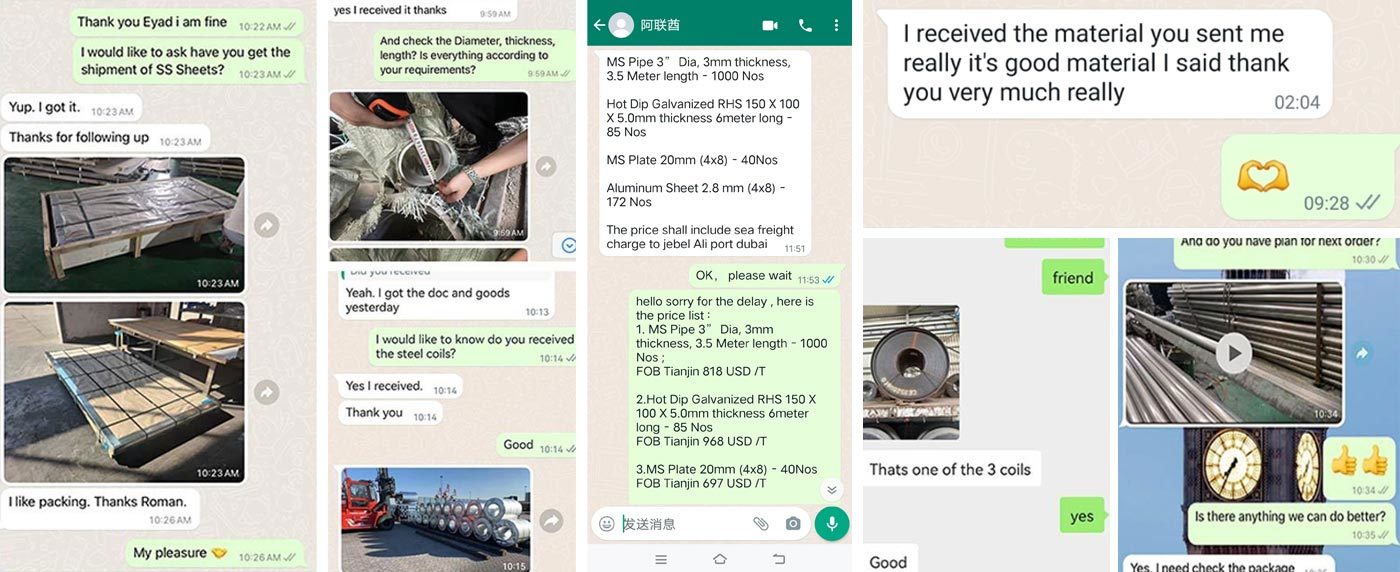

Customer praise

The company has been listed as an excellent supplier by a number of centralized enterprises, such as China Railway Group, China Electric Power Construction Group, China Road and Bridge Group, China Construction Corporation, etc., and has been rated as a Grade A Chinese steel enterprise for four consecutive years. Competitive Enterprise.

Customer Reviews

Jingye Steel Group is a one-stop provider of high quality steel solutions, with rich experience and excellent reputation in the steel industry

Application

The products are widely used in the construction of key projects at home and abroad, such as Beijing Daxing International Airport, South-to-North Water Diversion Project, Shijiazhuang Metro System, Xiongan Citizen Service Center, Brunei Sea Bridge, Pakistan Nuclear Power Plant, etc.

Related Products

GET A FREE QUOTE